Challenges and solutions in machining composite materials using specialized cutting tools

Composite materials are engineered materials that consist of two or more distinct components combined to create a superior material with enhanced properties. They are widely used in industries such as aerospace, automotive, marine, and wind energy due to their exceptional strength-to-weight ratio, corrosion resistance, and durability.

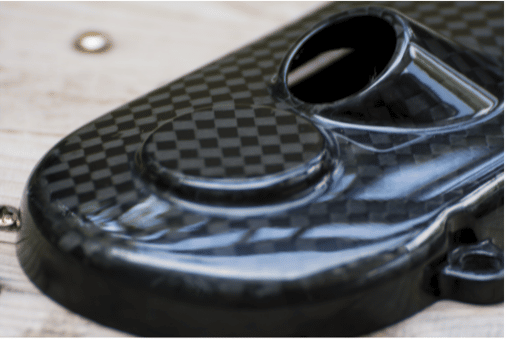

Machining composite materials presents unique challenges due to their inherent anisotropic nature and the presence of abrasive reinforcement agents such as carbon fibers. These materials are notorious for causing rapid tool wear, delamination, and surface defects when machined using conventional cutting tools. Therefore, specialized cutting tools like PCD tools are essential to ensure precise and efficient machining of composites.

Main Composite Families and Materials Requiring PCD Tools for Machining:

Fiber-Reinforced Composites:

- Carbon Fiber Reinforced Polymer (CFRP): Widely used in aerospace and automotive industries, CFRP offers exceptional strength and lightweight properties. PCD tools are crucial for achieving high-quality finishes and minimizing delamination during CFRP machining.

- Glass Fiber Reinforced Polymer (GFRP): Commonly used in construction, automotive, and wind energy sectors, GFRP combines strength with excellent electrical insulation properties. PCD tools are essential for precise cutting and reduced tool wear when machining GFRP.

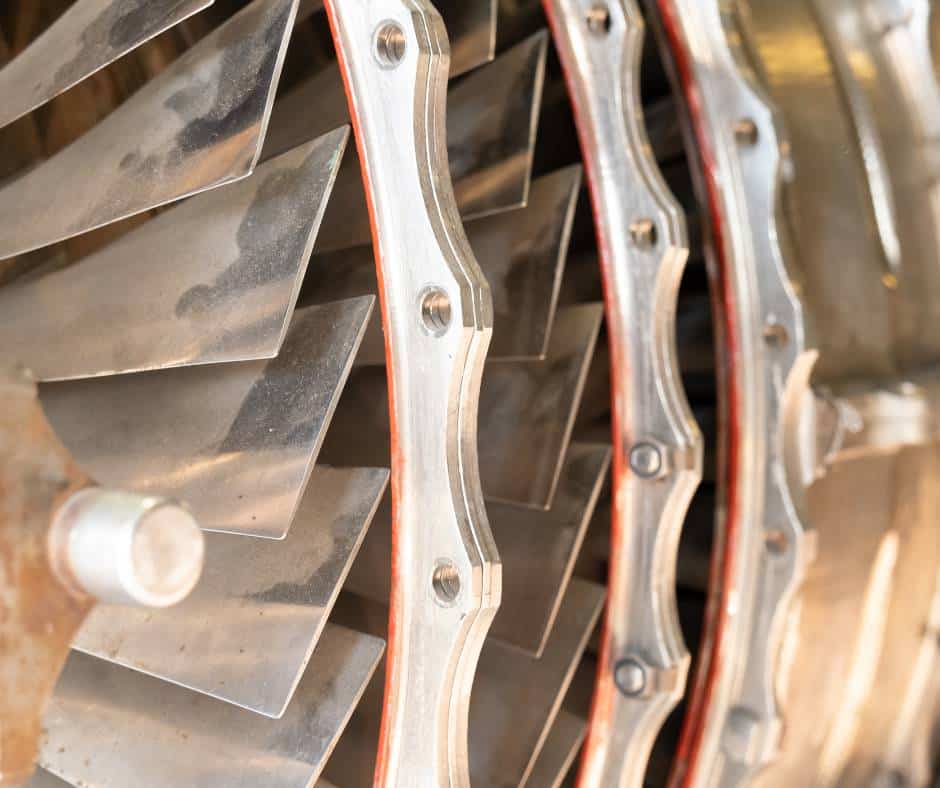

Metal Matrix Composites (MMCs):

Aluminum Matrix Composites (AMCs): Utilized in aerospace and automotive applications, AMCs offer improved mechanical properties and thermal stability. PCD tools are essential for efficient machining of AMCs while minimizing tool wear and achieving high surface finishes.

PCD tools for MMC: PCD drill fullnib, PCD endmill spiral RH, PCD End-mill – Multi Flute

Ceramic Matrix Composites (CMCs):

Silicon Carbide Matrix Composites (SiC/SiC): Prominent in aerospace and high-temperature applications, SiC/SiC composites offer excellent thermal and chemical resistance. PCD tools are indispensable for precise and reliable machining of SiC/SiC composites.

PCD tools for CMC: PCD drill fullnib, PCD endmill – Spiral, RH, PCD End-mill – Multi Flute, PCD Micro drills – Long, Abrasive tools, Multi-flute micro PCD endmills

Polymer Matrix Composites (PMCs):

- Thermoset Composites: These composites, such as epoxy-based materials, find extensive use in aerospace, automotive, and sporting goods industries. PCD tools ensure accurate machining of thermoset composites while minimizing tool wear and maintaining surface integrity.

- Thermoplastic Composites: Utilized in industries ranging from aerospace to consumer goods, thermoplastic composites like PEEK and PPS combine high strength with enhanced processability. PCD tools enable efficient machining and high-quality finishes while minimizing the risk of delamination.

High-Pressure Laminate (HPL):

HPL, or High-Pressure Laminate, is a versatile material produced stacking layers of different materials subjecting them to high heat and pressure. This process results in a dense and durable material with several desirable properties.

The materials are used in a wide variety of applications, PCD tools enable efficient machining and high-quality finishes while minimizing the risk of delamination.

PCD tools for HPL: Wafer tipped drill, PCD drill fullnib, PCD endmill – 2 FL, PCD endmill spiral RH

Tool Selection for different materials

Telcon supplies different tools for a verity of materials and applications, download our guide sheet to fit the right tools for your specific applications