In almost every airframe part there are predrilled holes.

During assembly process of these parts, final holes are drilled and parts connection is made.

While final holes during assembly process are done manually, almost all predrilled holes are done in CNC operation.

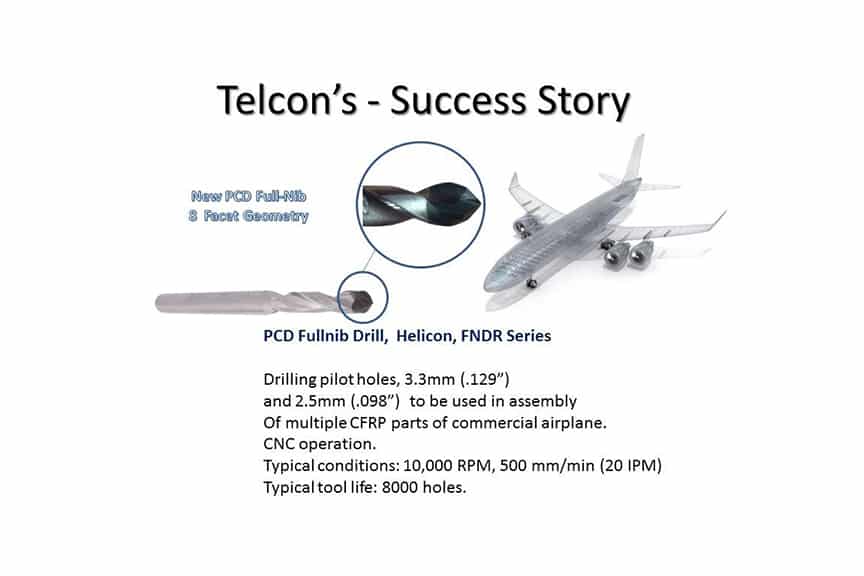

Telcon’s new designed PCD Full-Nib drill has improved cutting edge for composite materials, which allows smooth, non-delamination cut.

The smaller sizes, 2.5mm and 3.3mm are specifically designed for pilot (predrilled) holes.

These tools reach tool life of thousands of holes before reconditioning. Usually, 3 reconditioning cycles are possible.