What are Composite materials?

Composite materials are synthetic materials that are made from two or more material components with different physical or chemical properties that, when combined, produce a material with different (usually better) characteristics than each of the individual components, composite materials are commonly designed to serve specific purpose and the attributes of the material are designed to serve this purpose, for example carbon fiber materials that are designed for light weight and High strength with high brittleness.

Composite materials are in use in various applications in Aerospace, Automotive, Energy, Sports, Construction and more.

The fundamental advantage of composite materials is higher strength to weight ratio, which brings added value in the aforementioned applications.

In most cases, composite materials are constructed from two main materials: fibers of strong material, such as Glass or Carbon and a polymer matrix material, such as epoxy, which bonds the fibers together in a certain shape.

The table below summarizes the majority of composite material options:

| Fibers | Polymer Matrix (bond) |

| Carbon fiber | Epoxy |

| Glass fibers | Phenolic |

| Ceramic fibers | Polyimide |

| Polymer fibers (Kevlar, Polyethylene) | Poly-ether-ether-ketone (PEEK) |

| Tungsten fibers |

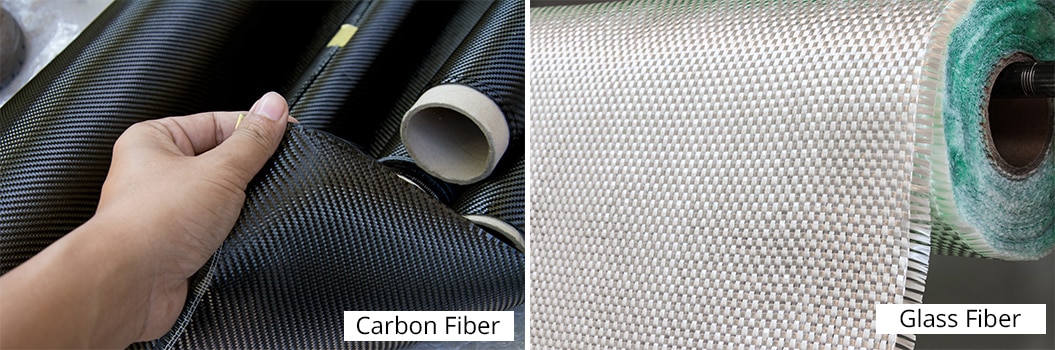

The two most advanced composite materials in use are Carbon Fibers, also called CFRP (Carbon Fiber Reinforced Polymer) and Glass fibers, also called GFRP.

About the Common types of Composite materials

Mass production of glass strands was accidentally discovered in 1932 when Games Slayter, a researcher at Owens-Illinois, directed a jet of compressed air at a stream of molten glass and produced fibers.

It wasn’t until the late 1950’s that high tensile strength carbon fibers were discovered. Rayon became the first precursor used to create these modern fibers. Ultimately, it was replaced by more effective materials such as polyacrylonitrile (PAN).

Between the two, GFRP is lighter and stronger, however, more expensive, therefore in use mostly in Aerospace and in luxury and sports cars and professional sport equipment.

Manufacturing process of composite materials involves three main technologies; the manufacturing of the fiber, the manufacturing of the polymers and the manufacturing of the combined composite material itself.

The process for making carbon fibers, which is part chemical and part mechanical involves the use of a precursor (About 90% of the carbon fibers produced are made from polyacrylonitrile, PAN) which is drawn into long strands or fibers and then heated to a very high temperature without allowing it to come in contact with oxygen. Without oxygen, the fiber cannot burn. Instead, the high temperature causes the atoms in the fiber to vibrate violently until most of the non-carbon atoms are expelled. This process is called carbonization and leaves a fiber composed of long, tightly interlocked chains of carbon atoms with only a few non-carbon atoms remaining.

It’s all in the fiber materials

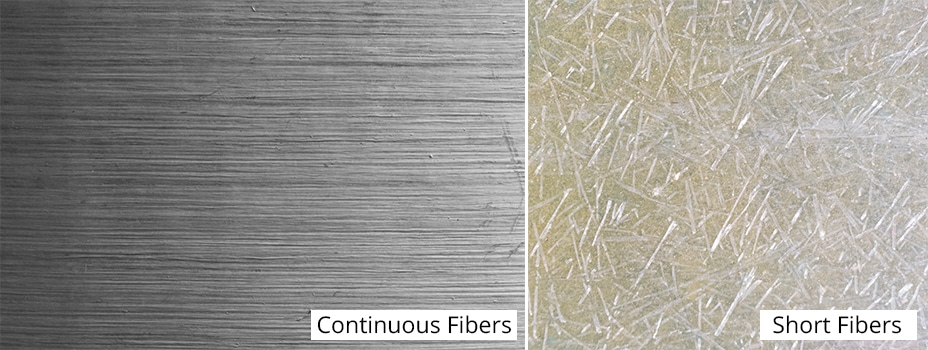

Fiber reinforced composite materials can be divided into two main categories normally referred to as short fiber-reinforced materials and continuous fiber-reinforced materials.

Continuous reinforced materials will often constitute a layered or laminated structure. The woven and continuous fiber styles are typically available in a variety of forms, being pre-impregnated with the given matrix (resin), dry, uni-directional tapes of various widths, plain weave, harness satins, braided, and stitched.

The short and long fibers are typically employed in compression molding and sheet molding operations. These come in the form of flakes, chips, and random mate (which can also be made from a continuous fiber laid in random fashion until the desired thickness of the ply / laminate is achieved).

In the next article we will discuss different manufacturing methods of composite materials, their pros and cons and their use in the industry.

More info