Nature of Thermoplastic composites in Aerospace

This article will explain about the two major composites matrices which are in use in the industry and particularly in the aerospace.

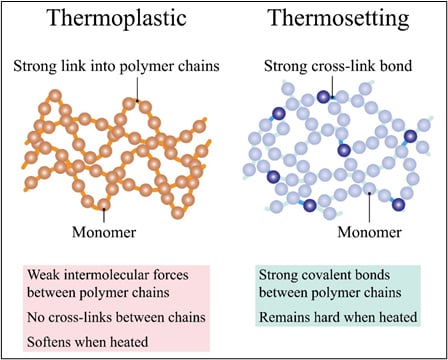

Most composite raw materials are purchased ready to be used by the part manufacturers. There are two major composites resin groups, ready to be used, which require different manufacturing methods; Thermoset matrix and thermoplastic matrix composites.

Thermoplastic composites are usually heated and molded or pressed into a mold to receive their final shape, then cooled and to final part is shape. The process involves only heating and cooling. The process is rather short and reversible. Since heating must take place immediately for the impregnation process, most of thermoplastic composites process are automatically done, involving in-situ consolidation, either in compression molding, filament winding

Thermoset composites layers are laid one on top of the other manually or automatically to the final part width and then oven-cured under vacuum bag to generate chemical reaction which brings them to their final solidification stage and properties. The process is longer and non-reversible.

The table below shows major differences between the two composites types:

| Thermoset Composites | Thermoplastic Composites |

| Generated during curing (chemical change) |

Generated by heating and cooling of the plastic matrix (physical change) |

| Non-reversible | Reversible |

| Easier to impregnate the fibers into the matrix in room temperature, Easier to process to final shape, thick to thin walls capabilities. | Impregnation can be done only during heating; therefore, reaching to final shape is more complex and costly. |

| Longer process cycle time due to Oven curing which takes few hours | Shorter process cycle time, no curing required, however, higher temperatures are required for the processing |

| Hard and rigid | Tougher and more flexible, therefore higher impact resistance |

| High fatigue strength | Lower Fatigue strength |

| Higher heat resistance | Lower heat resistance |

| Higher dimensional stability | Lower dimensional stability |

| Used mainly with continuous fibers | Used mainly with discontinuous fibers |

| Non-recyclable | Recyclable |

| Raw material must be stored in a specific environment and has limited shelf life | Regular storage conditions, unlimited shelf life |

| Cannot be welded, must be assembled with rivets and fasteners (adding the need for hole drilling and countersinking) | Under specific conditions, can be welded to other thermoplastic part |

To date, in Aerospace applications, more than 95% of prepregs are thermoset.

The nature of thermoset Composites

Thermoset composites have been successfully manufactured for aerospace since the 1960’s, and the knowledge is vast and mature. In addition, highly investment has been put during these years to develop processes, materials, equipment, gigs, training and testing for implementing the thermoset composites in aerospace parts.

Major structures in the Boeing 787, the Airbus A350 and Lockheed Martin F35 almost exclusively thermoset composites. Structural airplane parts such as fuselage, wings, beams, tails and others are made from Thermoset composites.

In the automotive, sports cars, supercars and some mass production cars, like BMW i3, are using thermoset composites.

All the energy windmills blades are made from thermoset composites.

Thermoplastics composites, on the other hand, were firstly used by Airbus on the A340, A380 and later, also on the A350. Up until recently, thermoplastic composites on airplanes have been used only for smaller parts like clips or brackets. This is gradually changing as better materials and processes are being developed while thermoplastic composites are being used in bigger parts in components like the horizontal stabilizer of the Leonardo AW169 helicopter, the rudder and elevators on the empennage of the Gulfstream G650. Additional parts were developed such as the fixed wing leading edge, keel beams, interior components, engine pylons, access doors, aircraft flooring and a variety of molded interior parts.

In fact, thermoplastic composites offer number of important advantages over thermoset:

It has higher degrees of impact toughness. It does not require special storage conditions. It does not need to be cured in autoclave for many hours. Two or more parts can be welded together saving the use of rivet connection (drilling & countersinking). And, it is more ecological since it can be recycled.

Why you will need high quality tools?

There are disadvantages for thermoplastics, which hold back a greater usage of these materials. The main disadvantages: impregnation of fibers can be done only during heating; therefore, reaching to final shape is more complex and costly. In addition, it has lower dimension stability than thermoset composites and has lower heat resistance.

Due to the nature of aerospace industry working under stringent regulations, it would still take years of investment in research and testing until thermoplastic composites will conquer higher volume of usage as compared to thermoset composites.

Telcon Diamond has developed over the years PCD and CVD solutions for both thermoset and thermoplastics composites. While thermoplastic composites involve less drilling and countersinking, the milling (routing) operation of these materials can be challenging since these parts are more flexible and elastic, therefore milling is less stable and tool geometry must be designed accordingly.