Diamond is a solid form of the element carbon with its atoms arranged in a crystal structure called diamond cubic.

Why do we use it diamond

Typically, natural diamonds age for between 1 billion and 3.5 billion years. Most were formed at depths between 150 and 250 kilometers in the Earth’s mantle. Some have come from depths of as much as 800 kilometers under high pressure and temperatures, where carbon-containing fluids dissolved minerals and replaced them with diamonds. Much more recently (tens to hundreds of million years ago), they were carried to the surface in volcanic eruptions and deposited in igneous rocks known as kimberlites.

Diamonds have the highest hardness and thermal conductivity of any natural material.

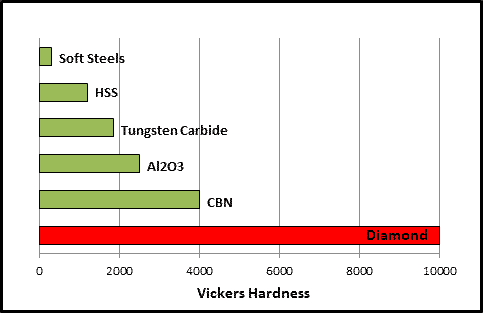

See the diagram below which emphasizes the level of hardness of diamond in comparison to other materials. The material with the next level of hardness is CBN which is less than half as hard as the Diamond.

Why do we use it diamond

Hardness is a fundamental property of a material to resist a force applied causing it to deform. Another interpretation of the diamond hardness would be higher wear resistance. It can be easily understood that when diamond is in abrasive contact with another material, the diamond would remove much more stock from the other material, than would be removed from the diamond itself.

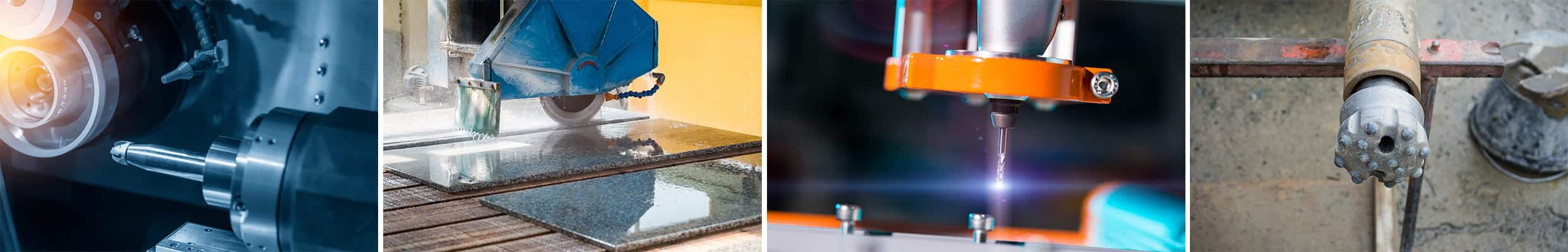

Clearly, due to higher hardness, diamond applications can be seen in the cutting tools industry. Diamonds are used in grinding wheels to grind hard metals, such as tungsten carbide or to cut and shape granite. Diamonds are being used as a cutting tool edge for the machining of non-ferrous abrasive materials, such as composite materials, hard ceramics, high silicone aluminum etc. Diamonds are also being used as a cutting edge in the road-header on excavating machines for roads, tunnels and mining.

Why do we use it diamond

The second advantage of the diamond as a cutting tool material is the thermal conductivity.

During machining, the cutting forces generate heat. The heat is distributed among 3 elements: the workpiece, the cutting tool and the removed material chips.

The high thermal conductivity of the diamond will ensure that large amounts of heat energy is dissipated in the tool itself and less to the workpiece. This protects the workpiece from thermal shock or deformation; this is mandatory, for instance, when machining carbon fiber reinforced plastic (CFRP). A higher heat level in the material might cause melting of the resin material while deteriorating the composite material’s mechanical properties.

Telcon has been manufacturing in-house cutting tools for more than 35 years and gained vast experience and expertise in the manufacture of Diamond PCD tools and solutions for various applications in the machining of composite materials. All cutting tool solutions (PCD drills, CVD drills, PCD end mills and CVD routers or PCD countersinks) are high quality and high performance, providing long tool life with non-delamination and non-bur issues.