Both PCD and carbide countersinks are commonly used in assembly and manufacturing processes, but what are the advantages of each type? what is the use case and when will we need to make the choice? in this article we will cover some of these questions in depth.

What is a Countersink tool?

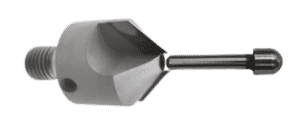

A Countersink (in short, CSK) is a cutting tool with edges tilted to a certain angle to create a chamfer at a certain size. The chamfer is mostly at the end of a hole in a manufactured part. The chamfer holds the head of a connecting element such as a bolt, rivet, or a screw, to have the head of this element align with the part surface.

What are Countersink tool types?

There are multiple applications for Countersink tools, in almost every industry, however we would like to focus on the usage in the aerospace airframe industry.

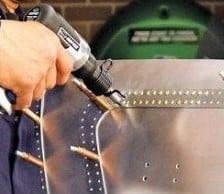

Countersink is a very common tool in the assembly lines of airplanes, since all body parts are attached and connected with rivets. The head angle of the rivet is 100 or 130 deg mostly and the Countersink tool angle is built accordingly by the Countersink manufacturer. Countersinks can be either with an integral pilot which is a part of the Countersink body, or with an exchangeable pilot, where the pilot is a made separately and inserted to a central hole in the Countersink . The pilot stabilizes and centers the position of the chamfer relative to the existing hole centerline in the part. The Countersinks are being held inside a stop-cage device, which allows setting up the depth of the Countersink penetration, hence the size of the chamfer given in the spec.

What applications with Countersink are at the airframe assembly lines?

There are two main applications for Countersinks, one which involves connecting parts made from Aluminum and second, parts made from FRP (Fiber reinforced plastic). There can be also a combination of both. There is not much difference in the way the Countersink tools are used in these two applications, there is, though, a major difference in the Countersink type. While in Aluminum parts, recommended Countersinks are with tipped carbide segments, on the Composites parts, recommended Countersinks are with PCD tipped segments.

PCD Countersink VS. Carbide Countersink

Understanding the difference between PCD and carbide, can explain some common mistakes end users are making while using the wrong countersink type for their application.

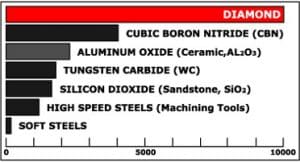

Composite materials are extremely abrasive due to the hard fibers inside their matrix especially in carbon fibers (CFRP). Choosing a carbide tipped CSK for this application is mistake no. 1.

PCD is 3-4 times harder than carbide. This explains the wear resistance advantage of PCD vs. Carbide in cutting composites. PCD tools can outperform a carbide tool by at least 20 times and show consistent quality results over much longer time compared to carbide.

People often compare only tool price and while PCD CSK may cost 2-3 times the price of Carbide CSK, that is mistake no. 2.

When using PCD Countersink vs. Carbide Countersink you would benefit from:

- Longer tool life by a factor of 20 at least.

- Consistent part quality over much prolonged time.

- Fewer setups.

- PCD CSK can have the option of resharpening and re-use at least twice.

Let’s compare “apples to apples”:

One PCD Countersink would in average make 1500 holes in CFRP, while carbide will make around 60 holes.

If we consider 2 re-condition cycles for PCD Countersink , that is a total of 4500 holes in one life span of a PCD Countersink.

| Carbide Countersink | PCD countersink | |

| Average cost, 1/2″ integral countersink, 100deg | 35$ | 80$

|

| Re-condition cost | N/R | 2×28$ = 56$ |

| Total Setup cost (in average 5min. to replace a tool and calibrate), average hourly cost of 60$ | For 4500 holes, 75 times CSK must be replaced, that is 375 minutes, or 6.25 hours, which ultimately cost 375$ | Total of 3 setup cycles, that is 15 minutes

15$ |

| Total tool cost for making 4500 holes | 35×75+375 = 3000$ | 80+56+15 = 151$ |

| Tool cost/hole | 3000/4500 = 0.67$ | 151/4500 = 0.033$ |

| Savings/Hole with PCD | 95% cost saving! |

There should be no doubt now, that PCD Countersinks are much better for using on composites.

Telcon Diamond Ltd. manufactures both types of Countersink tools made from the best PCD and carbide grades.

We can assist with your application – please contact us on: