Why you should try PCD dental milling tools

As part of the fabrication of dentures it is a common practice to bind yourself with one manufacturer for the Cad/Cam machine and get both the Dental blanks and the Dental Burs in one package, this package is supplied by the manufacturer and can be adequate.

However, in these packages hides a large loss for the dental lab, bringing both the price up and provides redundant elements that may not be needed as part of the package. Many dental labs are reluctant to move from the manufacturer options even if it is an inferior product to the existing options in the market.

Getting the Right Dental tool for the job

Dental milling tools are a great example for this, while the manufacturers mostly sell regular milling tools from solid carbide, in the market exist a vastly superior option: Telcon PCD Dental tools with much longer lifespan and the ability to keep the cutting edge for much longer periods and under heavy workload, reducing in inaccuracy caused by wear of the cutting edge by a large margin.

Using Telcon patented alternative tools in the Cad/Cam milling machine will get you up to X8 savings per crown compared to existing milling tools provided by the machine manufacturer, and that just in direct tooling costs, the number can radically increase when considering setup time and inaccuracy ratio.

Why Dental labs don’t change the dental burs they use today?

In many cases Labs are reluctant to swap the machine manufacturer as the milling tools supplier, this is caused due to two things:

- Simplicity: it’s close to home, it’s easy and you already know the supplier…

- Fear factor: will it annal my warranty? Will the new product fit in the machine?

It’s very easy to see why the Labs are reluctant to swap suppliers, however it’s also very easy to see why the swap is very lucrative! By saving the inherent costs in the process the lab can have more bang for the buck and save thousands of dollars each year.

Why use Telcon dental milling tools?

Telcon dental milling tools are the cream of the crop, the Patented unique tools provide up to X15 more crowns per tool then existing tungsten carbide tools. The tools are very durable and allow high speed processing of many crowns without losing the cutting edge or harming the crown accuracy. In addition, telcon tools are adapted to fit the chucks of Sirona, Amann Girrbach and Zirkonzahn Cad/Cam milling machine.

Telcon tools have a long history of success and performance in very demanding industries such as aerospace industry, Telcon has decided to use this expertise in the Dental milling tools industry to create a vastly superior product that can out preform the existing products in the market by a large margin.

Points:

- Bur Usage:

- Applicable materials: Zirconia and PMMA discs only.

- Cooling conditions: Dry or wet.

- Bur selection: Refer to machine manufacturer’s standards.

- Cutting Conditions:

- Preset in most CAD/CAM programs.

- Use tables below if no presets exist.

- Bur Information:

- Table details dimensions, catalog numbers, and compatible machine types.

Table: Bur Dimensions and Cutting Conditions

| Material | Bur Type | Diameter (mm) | RPM (Roughing) | RPM (Finishing) | Table Feed (mm/min) | Ap (mm) | Ae (mm) |

|---|---|---|---|---|---|---|---|

| Zirconia | Tungsten Carbide | 2.5 | 28,000 | – | 1200-1500 | 0.3 | 1.25 |

| 2.0 | 35,000 | – | 1200-1500 | 0.3 | 1.0 | ||

| 1.0 | – | 38,000 | 800-1000 | 0.1 | 0.1 | ||

| 0.6 | – | 63,000 | 500-600 | 0.05 | 0.05 | ||

| 0.5 | – | 64,000 | 500-600 | 0.05 | 0.05 | ||

| CVD Diamond | 2.5 | 28,000 | – | 1200-1500 | – | – | |

| SDT Diamond | 2.5 | 28,000 | – | 1200-1500 | – | – | |

| PMMA | Tungsten Carbide | 2.5 | 32,000 | – | 1300-1600 | 0.3 | 1.25 |

| 2.0 | 40,000 | – | 1300-1600 | 0.3 | 1.0 | ||

| 1.0 | – | 57,000 | 700-900 | 0.1 | 0.1 | ||

| 0.5 | – | – | – | – | – |

Note: Ap (axial depth) and Ae (radial depth) data are missing for some finishing conditions in the PMMA section. Refer to the manufacturer’s recommendations for these values.

Dental crown manufacturing – The 3 W’s

Dental crown manufacturing process

Dental crown manufacturing evolves a complex process that takes a few steps, from taking measurements through modeling and milling the crown.

while some of these steps are somewhat fixed our dental milling tools allow up to a 20 times increase in tool life which translate to major reduction in cost and shorter time of production due to reduced handling.

we will cover the process and background to show the best practice and your potential benefits with Telcon PCD dental milling tools.

About Dental crowns

What is a dental crown?

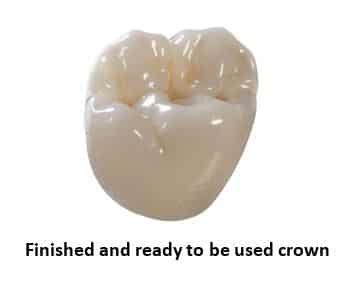

A dental crown or bridge is a full or semi artificial tooth. It can be made from several dental restoration materials such as Porcelain, Lithium disilicate, Alumina, Zirconia and Metals. The most common material used for making crowns is Zirconia. It is generally manufactured in soft phase (green state) and later sintered to final hardness and shape. Another common material is PMMA (polymethyl methacrylate) which is a plastic material used for most of the temporary restorations. Dental restorations are being made at the technician lab or at the dentist clinic, requiring multiple process steps, either conventionally, with negative impression plaster mold or with intraoral digital scan and cad-cam machines.

Why would we need a dental crown?

Dental crowns are needed to replace broken or missing teeth from functional and esthetical reasons. For example, we may have a broken tooth, which requires to be repaired. That can be done with Inlays and Onlays. If a tooth is too damaged to be fixed by a simple filling, an inlay or onlay may be used to repair the tooth.

Tooth that got a root canal treatment or severely broken tooth would get a complete crown or bridge with the shape of the normal tooth. The dentist attaches the restoration with special cement for permanent gluing, after milling the broken tooth to a certain shape in order to hold the crown firmly in its place.

A Full crown on top of a shaped tooth

A completely missing tooth would require either a bridge construction or an implant + crown.

When a bridge is done, the two adjacent teeth are prepared to a stage-like shape and the middle crown is supported by the two external teeth. Alternatively, an implant and abutment can be placed, and the new crown is adjusted accordingly.

When broken or missing tooth occur in the anterior (front) teeth section, the restoration is mainly done from esthetical reason. Functional reasons are more likely when several or all teeth are missing.

How dental crown is made?

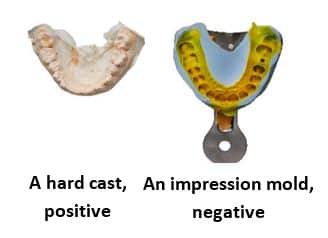

In case of crown or bridge covering broken teeth, the teeth must be reduced in size so that the crown or bridge will fit over it properly. In the next stage there are two options;

The conventional way is to use a tray with a silicon material impression, which the patient puts in mouth and bites. After a while the silicon material hardens and can be taken out, consisting the 3D shape of the relevant location. This impression is used later for creating another harder impression model cast of the positive shape to be used for measurements and scanning. The scanning information assist the technician to determine the shape of the new required tooth.

A Model Scanner

A more modern way is to use an intraoral digital scan of the prepared tooth in the mouth which makes the need to take impressions, redundant. The equipment required to perform these scans consists of a hand-held scanning tooth-brush-like stick that houses a miniature imaging system. This is connected to a hardware module that both powers the scanner and receives the digital generated image. This scanning file can be than used in a fabrication lab to eventually produce the crown.

Intraoral digital scanning

The fabrication lab uses the STL file to create in CAD (computer aided design) software the necessary shape of a crown to be mounted on top of the broken tooth or the missing tooth. When the file is ready, the same software turns the CAD file into a CAM (computer aided manufacturing) file to be transmitted to a dedicated 5 axis CNC machine.

In the process of Dental crown manufacturing there are different types of machines, from various manufacturers, such as: Amann Girrbach, Dentsply Sirona, Zirkonzahn and others, each one dictating the shape of the raw material, the dimension of the milling tools and the machining strategy, e.g. cutting speed, feeds, stock removals etc.

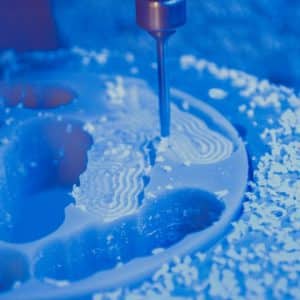

A zirconia disc during machining

The milling tools which are traditionally in use during dental crown manufacturing are made from tungsten carbide, capable of machining around 100 crowns (depending on size and shape).

Telcon Diamond Ltd is the first company to present PCD (polycrystalline Diamond) crown machining burs.

Since PCD is 5 times harder than Tungsten carbide, the PCD tools are much wear resistant, therefore life expectancy is 10-15 times more than the Tungsten carbide. In fact, 1500 machined crowns can be achieved on regular basis.

Another advantage is consistent high crown quality over time. While Tungsten carbide tools wear faster and lose their size (diameter) faster, deterioration of crown surface finish and dimensions is a fact. Inconsistent quality such as, mismatch, “wavy” surface and broken thin wall can be seen. The first and the last crowns are not within the same quality. With Telcon’s PCD tools, crown surface quality and dimensions are kept the same for much longer hours.

Telcon’s PCD crown milling burs are designed to be used in three machine platforms – Sirona Inlab MC X5, Zirkonzahn CAD/CAM M systems and Amann Girrbach ceramill mikro 5X.

Just replace your Tungsten carbide burs with Telcon’s PCD burs and press cycle start! https://telconpcd.com/product_cat/dental_tools

After zirconia crowns are manufactured, they should get their final working hardness within a sintering furnace. This process may take between 2 – 8 hours, depending on the hardness levels the lab would like to achieve.

No machining whatsoever is done on the crowns in hard state and the crown is practically ready. If specific coloring is required, then it should be applied prior to sintering.

Telcon Diamond Ltd is the only company who suggest a revolutionary process of machining the zirconia also in the hard state, that is, skipping the sintering process, saving time and material (due to 20% shrinkage in sintering). This machining process is under research and is likely to become productive in the near future.

Want to test our dental milling tools? click blow to order the tools now: